RIDGID WL1200 Owner's Manual Page 16

- Page / 52

- Table of contents

- TROUBLESHOOTING

- BOOKMARKS

Rated. / 5. Based on customer reviews

16

Assembly (continued)

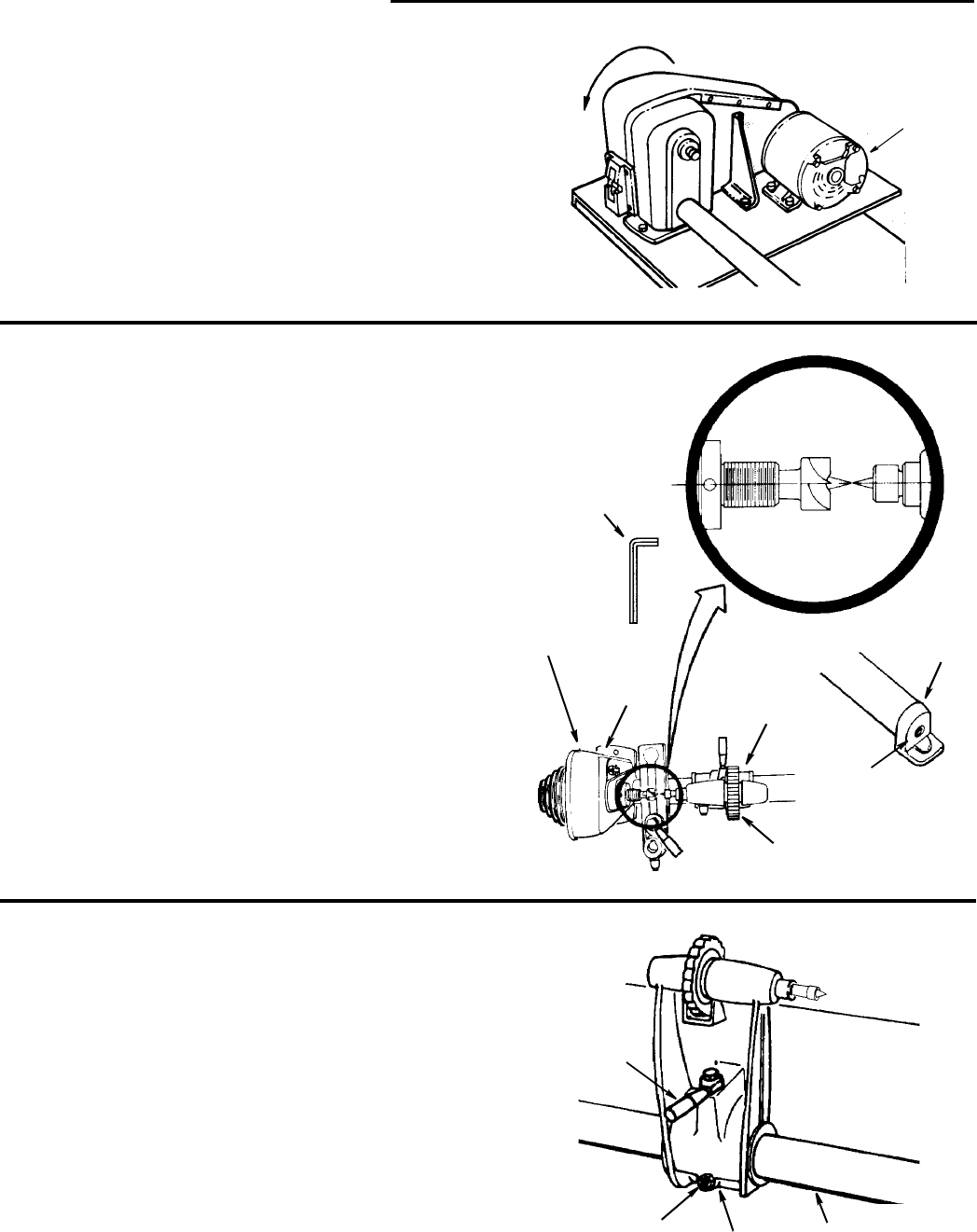

Check Spindle Rotation

The lathe spindle must rotate counterclockwise when

viewed from the spindle end.

NOTE: Make sure the spur center is removed from the

spindle.

1. Plug the lathe power cord into a properly grounded

outlet (See page 5)

2. Stand clear of the lathe spindle and turn the switch

On. Notice the rotation of the spindle. If it is Not turn-

ing Counterclockwise contact your Authorized Ser-

vice Center immediately before using this tool.

Aligning Centers

If the centers are not in line as shown, make the following

adjustments.

1. Make sure the tailstock and ram are locked when

checking for alignment.

2. Loosen the screw in the foot... Tap the screw to loosen

the locknut inside.

3. Using a 5mm hex “L” wrench, loosen the setscrew on

the back of the headstock. The screw is located about

1-3/4" from the bottom.

4. Swing the tailstock so that the two points are in line...

tighten the setscrew in the headstock and the screw in

the end of the tailstock.

Adjusting Tailstock

The tailstock contains a brass screw which bears against

the "key" on the underside of the bed. This screw prevents

excessive "looseness" (rocking back and forth) of the tail-

stock.

1. Loosen the locknut using a 13mm wrench.

2. Tighten the screw moderately against the key, then

loosen it about 1/4 turn.

Slide the tailstock along the bed. If it does not stick or bind

in any one spot, tighten the nut. If it binds or sticks, loosen

the screw only enough so that the tailstock slides smooth-

ly along the bed.

Rotation

Terminal

Cover

5mm Hex “L”

Wrench

Headstock

3/16"

Set Screw

Tailstock

Handwheel

Screw

Foot

Tailstock

Lock

Brass

Screw

Locknut

Key

- Table of Contents 2

- Safety Signal Words 3

- Before Using the Lathe 3

- Before Each Use 3

- Inspect Your Workpiece 4

- Whenever Lathe Is Running 5

- Before Leaving the Lathe 5

- Wire Sizes 6

- Check Motor Rotation 6

- Tools Needed 6

- Unpacking 6

- List of Loose Parts 7

- Assembly 8

- Mounting Left Side Table Top 9

- Assembly (continued) 10

- Mounting Headstock 11

- On-off Switch 18

- Speed Chart 18

- Basic Lathe Operations 19

- Spindle Turning 20

- Indexing 21

- Theory Of Turning 22

- Selection Of Chisels 22

- Diameter 23

- Using The Gouge 24

- Using The Skew 24

- UsingWoodRaspsAndFiles 26

- Hand Positions 26

- Making Standard Cuts 27

- Duplicate Turnings 31

- Long Spindles 32

- Miscellaneous Operations 33

- How to Turn Plastics 38

- Wiring Diagram 41

- Maintenance 41

- Troubleshooting 42

- Motor Connections 44

- Repair Parts 45

- CALL 1-800-4-RIDGID 52

(6 pages)

(6 pages)

Comments to this Manuals